Egypt’s bold entry into advanced automotive manufacturing is being crystallized through the launch of the $150 million MAC Automotive plant in 6th of October City a facility that symbolizes Egypt’s transition from vehicle importer to competitive regional producer. While Egypt has long aspired to develop an integrated automotive industry, the MAC project signals a decisive shift in strategy: building a modern, technology-driven, export-capable ecosystem that aligns with global transportation trends. This facility is emerging at a critical moment when countries worldwide are accelerating electric mobility, restructuring supply chains, and reassessing industrial competitiveness. For Egypt, the MAC plant is more than a factory; it is a strategic industrial anchor, a catalyst for economic growth, and a platform for national technological advancement.

A New Industrial Flagship for Egypt

Historically, Egypt’s automotive industry has experienced waves of growth and stagnation. In the early 20th century, Egypt was one of the first Arab nations to assemble vehicles locally, working with European partners. However, the sector did not keep pace with global modernization due to limited investment, inconsistent policies, and a fragmented supply chain.

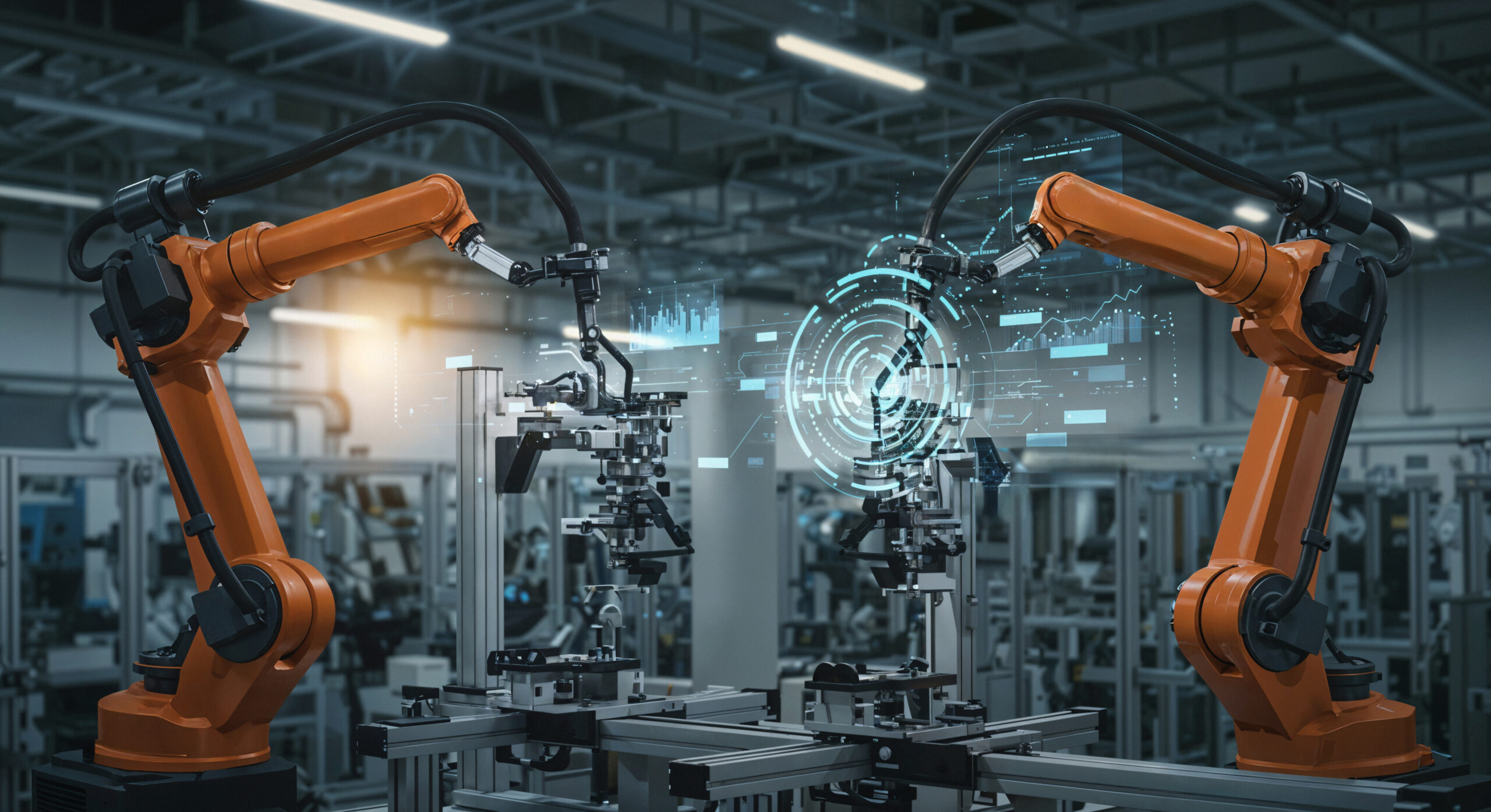

The MAC plant represents a decisive break from this past. It embodies modern global standards, incorporating automation, digital manufacturing systems, quality certification labs, and flexible production technologies that enable rapid model changeovers. Its dual-platform manufacturing producing both conventional combustion vehicles and next-generation electric models equips Egypt with capabilities that few countries in Africa and the Middle East currently possess.

This facility also positions Egypt for future technological shifts such as autonomous driving assistance, advanced vehicle software integration, and smart mobility systems. By embedding these capabilities early, MAC is helping Egypt leapfrog legacy-style assembly into fourth-generation automotive manufacturing, where data, sensors, energy efficiency, and electronics play critical roles.

Production Capacity and the Roadmap to Expansion

The production roadmap has been engineered to scale steadily and sustainably. During the initial phase, MAC will focus on producing 50,000 vehicles annually with a core emphasis on cleaner, more fuel-efficient models suitable for urban mobility and government fleets. This phase also involves testing the logistics framework, onboarding suppliers, and integrating robotics and quality control technologies into daily operations.

As the plant enters its second phase, it evolves into a multifunctional production hub with a diversified vehicle portfolio. Fully electric sedans, commercial EVs, and hybrid models will be introduced, targeting both domestic and regional markets. Managing production at 100,000 units annually requires local supplier consolidation, engineering innovation, and enhanced worker specialization all areas where MAC is already investing heavily.

Looking ahead to the third phase, Egypt plans to turn the MAC complex into a central node for export manufacturing. With Africa’s vehicle demand projected to exceed 5 million units annually by 2035, the continent represents a vast untapped opportunity. MAC aims to serve this rising demand through competitive pricing and locally adapted vehicles. The possibility of local EV battery pack assembly further indicates Egypt’s long-term strategic aim to control critical components of the mobility value chain.

Economic Impact: Beyond Vehicle Manufacturing

The economic implications of the MAC plant reach far beyond car production. Automotive manufacturing is one of the world’s most influential industries, generating strong multiplier effects across sectors such as metallurgy, electronics, plastics, chemicals, engineering, and logistics. As the MAC plant grows, dozens of tier-1 and tier-2 suppliers are expected to set up operations nearby, creating new business clusters.

In addition, the factory will stimulate demand for upstream industries like raw materials, industrial machinery, and packaging, while also boosting downstream sectors such as maintenance services, dealership networks, after-sales support, and vehicle financing. The thousands of jobs created directly and indirectly feed into local economic revival, making the automotive sector a powerful driver of regional development.

Furthermore, the technology-transfer aspect of the project is especially significant. Workers trained in EV engineering, automotive electronics, digital diagnostics, and assembly automation will elevate Egypt’s broader labor market capabilities. This contributes to long-term national skills development one of the most vital components of sustainable industrialization.

Local Content and Government Policy Integration

Egypt’s industrial policies are evolving to address modern global manufacturing realities. NAIDP, which underpins the MAC project, uses targeted incentives to increase domestic value creation. This includes reducing customs duties for manufacturers reaching higher local content thresholds, giving preferential treatment in public procurement, and granting tax advantages for export-oriented production.

Increasing local content from 35% to more than 60% is not simply a policy goal it is a framework that unlocks an entire ecosystem of domestic suppliers. Egyptian companies specializing in wiring harnesses, upholstery, steel components, electronics, plastics, and glass manufacturing are now positioned to participate in a stable, high-demand market.

At the macroeconomic level, boosting local production reduces Egypt’s dependency on imported vehicles, helping stabilize foreign currency reserves. This aligns industrial growth directly with economic resilience, making the MAC plant a strategically important contributor to national economic stability.

Why This Project Matters for the Region

The MAC plant arrives during a period of intense competition within the regional automotive landscape. Morocco has become a world-class production and export hub, supplying Europe with millions of vehicles through partnerships with Renault and Stellantis. Turkey is similarly competitive, strengthened by its proximity to Europe and deep integration into European supply chains. Saudi Arabia and the UAE, meanwhile, are pushing aggressively into electric mobility, investing in homegrown EV brands, smart cities, and innovation-driven automotive projects.

Egypt positions itself as a unique player among these markets. Unlike Morocco, whose production is largely export-driven, Egypt has a massive domestic market that supports consistent demand. Unlike the Gulf states, which are investing in futuristic high-end EV brands, Egypt is focusing on scalable mass production, targeting affordable models suitable for African, Middle Eastern, and domestic consumers. This strategic positioning enables Egypt to serve as a bridge between mass-market African mobility and technology-focused Gulf mobility giving the country an unmatched competitive advantage in regional automotive trade.

Green Mobility and Sustainability Compatibility

Egypt’s clean energy transition forms a natural backbone for the MAC plant’s green mobility direction. With the world’s largest solar parks and ambitious wind energy projects, Egypt is steadily building a cleaner electricity ecosystem. As EV adoption increases, this renewable push will reduce emissions even further, making locally produced electric vehicles more environmentally valuable.

The government is also rolling out incentives for EV buyers, including reduced customs duties, free licensing periods for EVs, and dedicated parking and charging facilities in major cities. Pilot projects for electric buses have already begun in Cairo, Alexandria, and new urban developments. These initiatives create a supportive environment for MAC’s hybrid and electric models, reinforcing the long-term sustainability of the project.

Challenges and Structural Considerations

Despite its potential, Egypt’s automotive transformation must navigate several challenges. The lack of localized battery manufacturing remains a critical bottleneck. Batteries account for up to 40% of the cost of an electric vehicle, making local production crucial for competitiveness.

Another challenge lies in strengthening Egypt’s engineering ecosystem. Developing a full-fledged automotive R&D sector requires partnerships with universities, technical institutes, and international technology providers. Sustained innovation is key if Egypt wants to move beyond assembly into design, engineering, and advanced manufacturing.

Moreover, global supply chains are undergoing structural shifts due to geopolitical tensions, economic fragmentation, and technological disruption. Egypt must position itself not only as a cost-competitive producer but also as a stable, reliable partner for global manufacturers navigating uncertain global trade dynamics.

Strategic Outlook

The MAC Automotive plant is poised to redefine Egypt’s long-term industrial identity. It sets the foundation for Egypt to emerge as one of the leading automotive producers in Africa and the Middle East not through volume alone, but through technology, innovation, skilled labor, and sustainable mobility leadership.

As global demand shifts toward EVs, autonomous technologies, and cleaner transportation systems, Egypt’s early investment through MAC positions the country to be part of the next generation of global mobility. The next decade will determine how far Egypt can push its competitiveness, but the direction is unmistakably clear: the country is moving toward a modern, diversified, export-driven industrial economy, and MAC Automotive is one of the strongest pillars supporting that transition. The plant is not just a milestone it is the launchpad for Egypt’s industrial future.

Related Blogs : https://arabworldleaders.com/category/articles/